Back to overview

Natural dye making

I will document my experiments with natural dyes here. Be sure to check out the slides for Fabricademy by Cecilia Raspanti.

Overview

It’s good to know what we’re talking about so I’ll start with a little lexicon.

| Dye | Liquid bath | Water soluble | Into the material |

| Ink | Dense liquid | Water soluble | Into the material |

| Pigment | Powder | Not water soluble | Onto the material |

| Vehicle/solvent | The liquid in which the pigment is suspended. For example water, ethanol (96% alcohol), oil or gel. |

| Binder | Sometimes needed to merge the color with the vehicle (for example arabic gum). |

| Mordants | Dye fixatives that are used to ‘adhere’ the dye to the fiber. They enhance the light- and wash-fastness. Alum, iron and copper are typically used (but they can also have an influence on the final color). Mordants can be used before, during or after dyeing. |

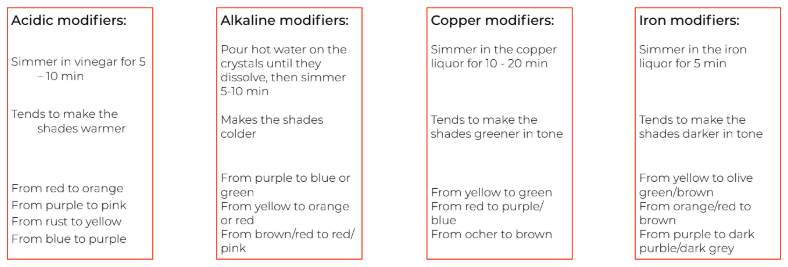

| Modifiers | Substances that can change the hue of the dye. |

| pH modifiers | Substances that change color by changing the pH level toward more acidic (vinegar, citric acid, alum), or more alkaline (sodium carbonate). |

| Metal modifiers | Copper modifiers make the colors duller and darker, and can bring out blue and green shades. Iron modifiers make the colors duller and darker. |

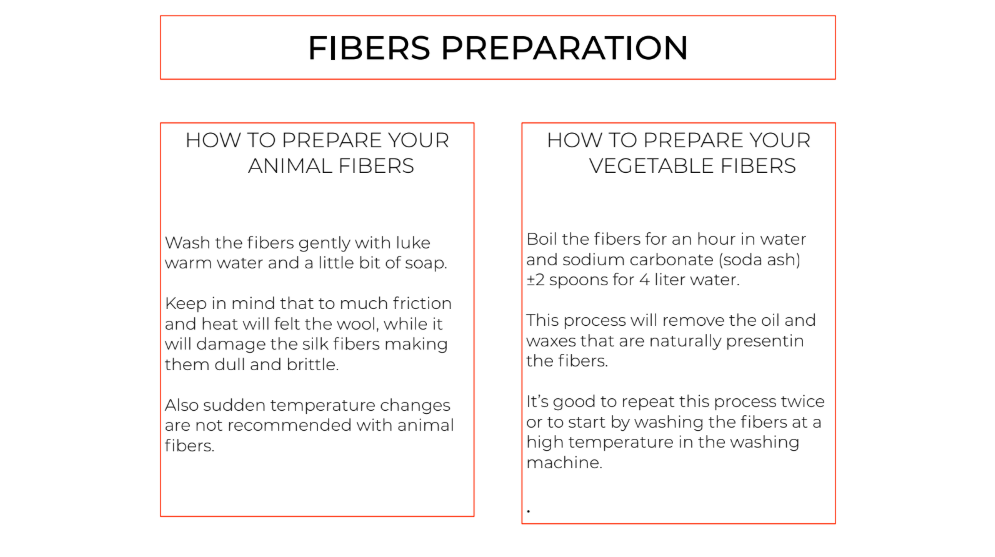

| Boiling fibers | Don’t boil or shock animal fibers. Keep them simmering at 80 degrees Celsius, and don’t rinse them in cold water straight after that. You can boil and shock cellulose fibers. |

| Scouring | Cleaning the fibers (especially vegetable fibers) with scouring agents like sodium ash (sodium carbonate/natrium carbonate). This is done to prepare the fabrics (removing waxes, pectins, dirt etc.) and make it more water absorbent. |

| Stabilizers | Stabilizers help with the even distribution of color in the water and onto the material (often salt is used). |

| Kind of ink | Vehicle |

|---|---|

| Regular inks | Water (liquid in which the pigment is suspended) |

| Marker inks | Ethanol (96%) (substance that acts like a glue) |

| Printing inks | Oil/gel (substance that stabilises, intensifies & thickens the ink) |

“To stabilise and preserve the water based ink salt is a great addition, acids and alkali can be used to change to look of the colour, while arabic gum helps to thicken and stabilise the inks. Marker inks do not require salts and guar gum to be added.”

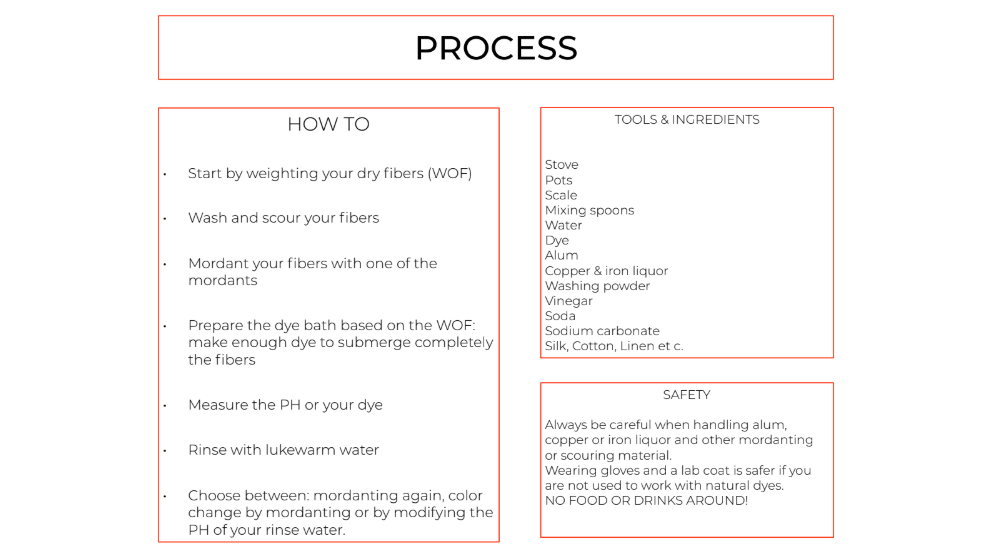

Fabric dyeing process

Notes

- Use fresh (not dried) materials as the colors will be less bright

- Natural materials (wool, cotton, silk, linen) work best